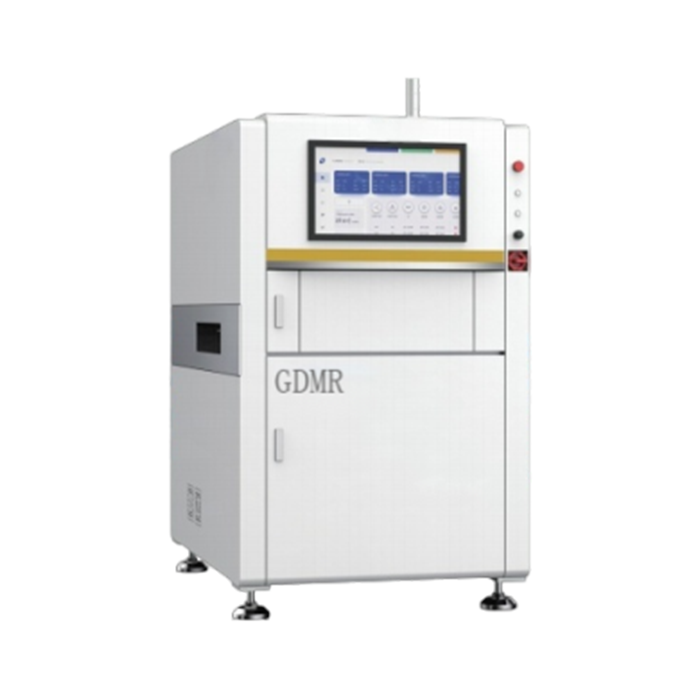

Introduce of SMT Online 3D SPI MR-8080

1. Solve shadow effect interference in solder paste 3D detection. The combination of RG 2D light source perfectly

handles high contrast substrates, such as black substrates, ceramic substrates, etc. Using red, blue, and green

light, color 2D images can be provided.

2, high resolution image processing system: ultra-high frame number 5 million pixels industrial CCD camera, with

high-end telecontrol lens, support 01005 solder paste rapid and stable detection. At the same time, it provides

a variety of different detection accuracy such as 15um, 18um, 20um, etc., to meet the requirements of customer’s

product diversity and detection speed.

3, fast Gerber import and programming software, can achieve the industry’s fastest 5-minute programming; Manual

Teach function is convenient for users to program and detect when there is no Gerber data.

4, Z-axis real-time dynamic copying: the characteristics of PSLM provide real-time dynamic tracking of PCB

warping changes, perfect solution to flexible circuit boards and PCB warping problems.

5, powerful process statistical analysis function (SPC)

6, repeatability accuracy <<10%(6 Sigma).

Specification of SMT Online 3D SPI MR-8080

| Model |

|

MR-8080 |

| PCB Direction |

PCB Size |

55*55 ~460*460mm (470*500 as option) (630*686 as option)

|

| Rail Fixed |

front fixed (back fixed as option) |

| PCB Tickness |

0.5 ~ 7.0mm |

| PCB Weight |

≤5.0kg |

| Conveyor Adjustment |

Manual/automatic |

| Conveyor Height |

900±20mm |

| PCB Direction |

Left ~ Right(Right ~ Left) |

| Measurement System |

Measure Type |

Height,Area,Volume,Offset,Bridge,Shape(missing print,insufficient

tin, excessive tin, bridging, offset, mal-shapes, surface contamination) |

| Paste Height |

0 ~ 550um |

| Accuracy |

XY (Resolution):10um |

| Repeatability Height |

≤1um (4 Sigma), volume/acreage:<1%(4 Sigma) |

| Min Pad Pitch |

≥100um |

| Measure Principle |

3D white light PSLM PMP(Programmable Spatial Light Modulation, Phase

Measurement Profilometry) |

| Inspection Head Quanlity |

1 |

| Camera Pixel |

5M, (10M/12M as option) |

| Optical Resolution |

4.5um/5um/6um/8um/10um/12um/15um/16um/18um/20um |

| Minimum Chip |

01005(03015/008004 as option) |

| Detection Speed |

0.35 ~ 0.5s/FOV |

| Software System |

Language |

English |

| Program Mode |

Off line or on line |

| Program Time |

5 ~ 10min |

| Data Type |

Gerber Data 274D/274X, Scan PCB |

| SPC & Process Monitoring |

Standard SPC |

| Drive Mode |

Servo Drive |

| Machine Direction |

Power |

AC220,50/60Hz,1KVA |

| Air Pressure |

0.35 ~ 0.6Mpa |

| Machine Dimension |

W1000*D1150*H1530mm |

| Weight |

965kg |

| Option |

One person controls more machines,Network SPC(Software only),1D / 2D

Barcode scanner,out-line programming software, UPS continuous power supply. |