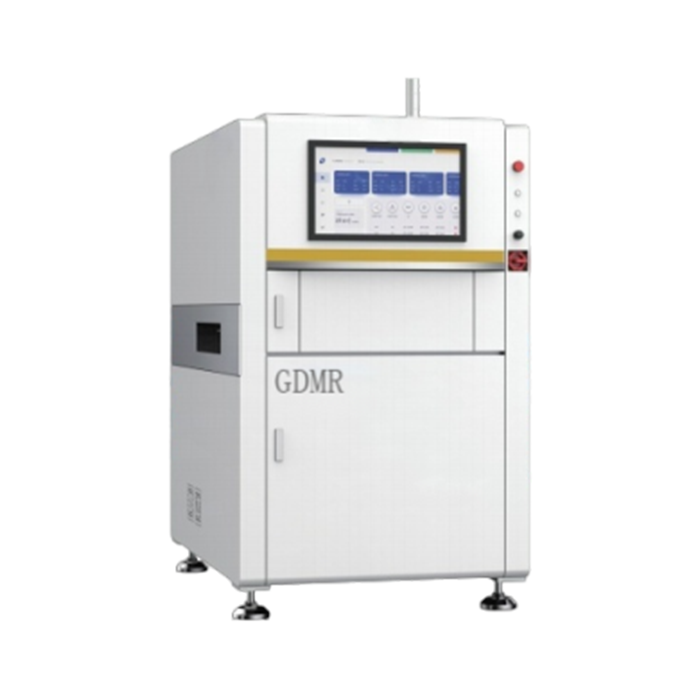

Introduce of online 3D AOI AI-TD5146

1.The world’s first use of programmable structure grating (PSLM) technology to form a full spectrum structure

grating. Compared with the traditional fixed glass moire grating, the software modulation and control of the

structure grating are realized. It greatly improves the detection ability and application scope of the

equipment.

2.It adopts AI intelligent seamless jigsaw puzzle technology to reach the level that cannot be distinguished by

naked eyes. It greatly facilitates the production and debugging of the program, and reduces the possibility of

false positives.

3.The enhanced multi angle, multi region, adjustable RGB + W 2D light source design is adopted. It is suitable

for the detection of components, solder joints and characters in various situations.

4.Intelligent program editing method and template parameter setting method are adopted. It is convenient to write

and debug programs quickly.

5.2D + 3D body positioning technology ensures accurate body positioning of black and other special components.

6.CXP camera with high frame number ensures the industry leading test speed.

7.The optional 4 projection head + 8 projection head detection scheme covers all SMT applications.

8.Perfect SPC analysis software and dead cycle control settings ensure data traceability.

Specification of online 3D AOI AI-TD5146

|

Model

|

AI-TD5146

|

|

Measurement Principle

|

Sine white projection PMP inspection

|

|

Measurements

|

Missing parts, offset, rotation,three-dimensional polarity, upside down, OCV , side standing,

tombstone, poor soldering, etc.

|

|

Detection of Non-Performing Types

|

Solder tip, solder volume percentage,excessive solder, insufficient solder, bridge, hole

plugging, solder filet, pad contamination, etc.

|

|

Lens Resolution

|

42mmx42mm (based on 6. 5 M pixel / 16.5um resolution)

|

|

Accuracy

|

XY (Resolution):±1um

|

|

Repeatability

|

height:≤1um (3 Sigma);volume/acreage:<1%(3 Sigma)

|

|

Gage R&R

|

<<10%

|

|

Inspection Speed

|

0.45 SEC/FOV

|

|

Quanlity of Inspection Head

|

4(8 head is option)

|

|

Mark-point Detection Time

|

0.5sec/piece

|

|

Maximun Meauring Head

|

30mm

|

|

Engineering Statistics

|

SPC:Production Trend;Xbar-R Chart;Xbar-S Chart;CP&CPK;%Gage Repartability Data;AOI

Daily/Weekly/Monthly Reports

|

|

Mini Component

|

01005chip,0.3pitch IC and Special shaped

|

|

Operation System

|

Windows 10

|

|

Max.PCB Size

|

510*460mm

|

|

Conveyor Type

|

Single lane

|

|

PCB Thickness

|

0.3 ~ 6.0mm

|

|

PCB Warpage

|

±2.0mm

|

|

PCB Weight

|

Max:4Kg

|

|

PCB Height

|

Top:50mm

|

|

Conveyor Height

|

900±20mm

|

|

Conveyor Direction

|

L ~R or R ~L

|

|

With Adjustment

|

Manual or Auto

|

|

Power

|

AC220 50/60Hz,5A

|

|

Compressed Air

|

0.4 ~ 0.6Mpa

|

|

Weight

|

1100Kg

|

|

Dimension

|

W1156*D1475*H1640mm

|

|

Optional

|

1 D /2 D Barcode Scanner; Badmark Function; three-point function; offline programming; Repair

Station

|