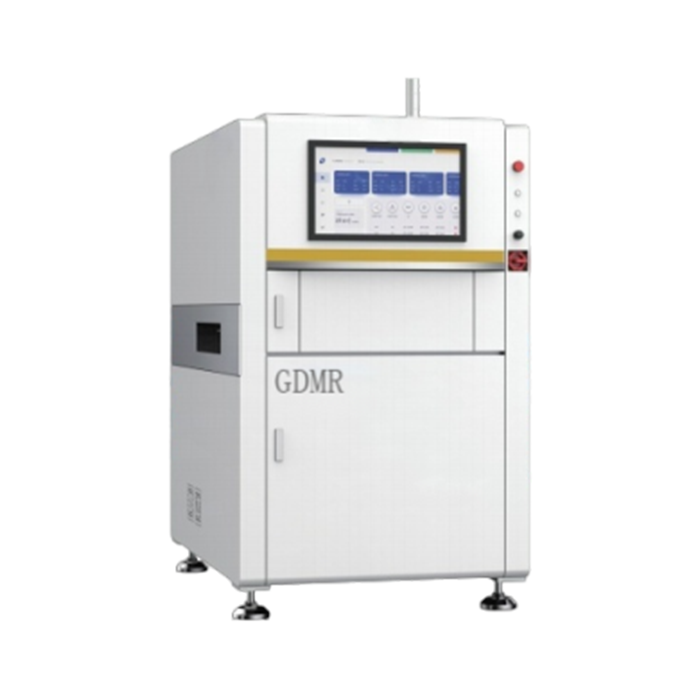

| Model |

MR-680 |

|

| Detection Capabilities |

Applicable process |

After SMT solder paste printing, before/after SMT reflow, before/after DIP

wave soldering |

| Programming Mode |

Manual writing, automatic writing, CAD data import automatically corresponds

to the component library |

| Detection Type |

Solder paste printing: presence or absence, offset, insufficient solder,

excessive solder, disconnection, solder connection, contamination, scratches, etc. |

| Parts defects: missing parts, extra parts, offset, skew, upright, sideways,

flipped parts, wrong parts, broken parts, reverse parts, etc. |

| Solder joint defects: too much tin, too little tin, cold solder joint,

bridging tin, tin balls, overflowing glue, pins not coming out, copper foil contamination, etc. |

| Calculation method |

Color calculation, color extraction, grayscale calculation, image

comparison, etc. |

| Detection Mode |

Optimized detection technology covering the entire circuit board,

panelization and multi-marking, including Bad mark function |

| SPC statistics function |

Record test data throughout the process and perform statistics and analysis.

Production status and quality analysis can be viewed in any area. |

| Part Angle |

Supports 0-359° rotation, minimum 1° angle |

| Smallest parts |

0201 chip、0.3 pitch IC |

| Optical Configuration |

camera |

Full color high speed industrial digital camera |

| Lens resolution |

10um/15um/18um/20um/25um,特殊应用时可订制 |

| light source |

Ring-shaped stereoscopic multi-channel color light, select according to

application RGB/RGBW/RGBR/RWBR |

| Computer |

CPU |

Intel Core |

|

| VGA |

NVIDIA 1GB+ |

|

| RAM |

4GB |

|

| HDD |

500GB+ |

|

| OS |

Win 7 64bit |

| Monitor |

22寸,16:10 |

| Mechanical system |

Shipping and testing methods |

Manual board placement, Y servo motor moves PCB, X servo motor drives camera

to take pictures |

| PCB Size |

20*20mm(Min)~460*350mm(Max), |

| PCB thickness |

0.3~5.0mm |

| PCB weight |

Max:3KG |

|

| PCB Board edge |

3mm |

| PCB Curvature |

<5mm or PCB of the diagonal length |

| PCB Part Height |

Top:35mm,Bottom:75mm。 |

| XY Drive system |

AC Servo motor, precision ground ball screw |

| XY Movement Speed |

Max:830mm/s |

|

| XY Positioning accuracy |

≦8um |

|

| Machine parameters |

Equipment dimensions |

L900 * W1100 * H1400 mm |

| power supply |

AC220V,50/60Hz,1.2KW |

| PCB Height from ground |

820±20mm |

| Equipment weight |

360KG |

| Front and rear equipment communication |

— |

| Air pressure requirements |

no need |

| Equipment safety regulations |

Complies with CE safety standards |

| Ambient temperature and humidity |

10~35℃, 35~80% RH (no condensation) |