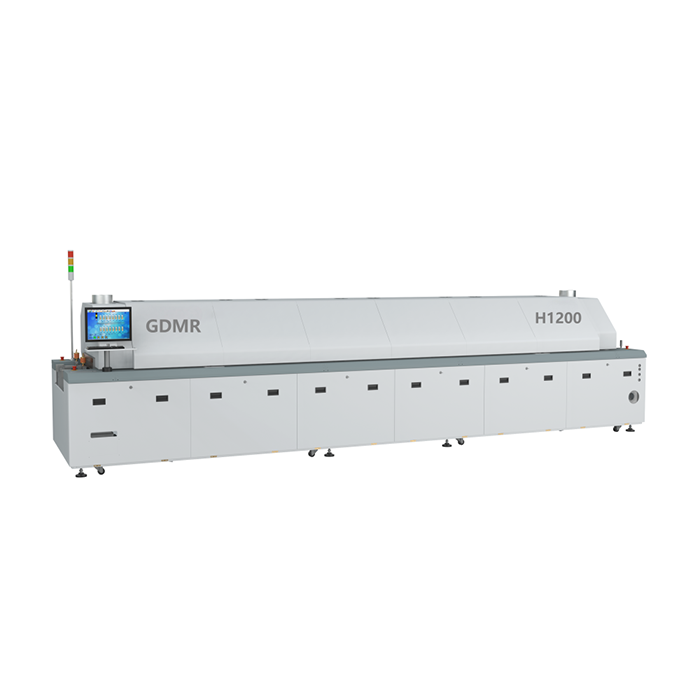

No. | Item | VH0813 | VH1013 |

1 | Dimension | L6400*W1695*H1650 | L7170*W1695*H1650 |

2 | Weight | 3000KG | 3500KG |

3 | Number of heating zone | Top 8 /Bottom 8 | Top10 /Bottom 10 |

4 | Length of heating zone | 3110mm | 3892mm |

5 | Number of cooling zone | Top 3 /Bottom 3 | Top 3 /Bottom 3 |

6 | Exhaust volume requiement | 11m³/min*2 | 12m³/min*2 |

7 | Power | 3phase, N,PE;AC380V50/60HZ | 3phase, N,PE;AC380V50/60HZ |

8 | Total power | 67KW | 83KW |

9 | Startup power | 32KW | 38KW |

10 | Normal power consumption | 10KW | 12KW |

11 | Warming Time | Approx:20min-25min |

12 | Temperature control range | Room temperature -300℃ |

13 | Temperature control Mode | PID close loop cont+SSR driving |

14 | Temperature control precision | ±1℃ |

15 | Temperature deviaation on PCB | ±1℃ |

| Conveyor system |

16 | Rails structure | Three-stage independent |

17 | Max width of PCB | 150*150MM-400*400MM |

18 | Range of rail width | 50mm-400mm |

19 | Components height | Up 30mm/down 30mm |

20 | Conveyor direction | L-R |

21 | Conveyor fixed type | Front end fixing |

22 | PCB conveyor direction | Guide rail plus chain |

23 | Conveyor height | 900±20mm |

24 | Conveyor speed | 300mm-2000mm |

25 | Auto-lubrication | Can set a variety of automatic or manual filling high temperature lubricating oil |

| Vacuum chamber transport |

26 | Width modulation | Three-stage synchronous width adjustment |

27 | Vacuum chamber mode of transport | Independent transport |

28 | Ultimate vacuum | 50PA |

29 | Vacuum extraction method | Four-stage independent vacuum |

| Cooling system |

30 | Cooling method | Forced air cooling (vacuum reflow soldering) Chiller cooling (vacuum nitrogen reflow soldering) |

Options |

31 | Nitrogen System | Nitrogen confined structures and pipelines, nitrogen flow meters, chillers |

32 | Anti-stuck structure | No affects by PCB thickness, no manually adjusting to solder products of different thickness, 1mm-2mm-3mm can be soldered |