【Origin Pic】 |

|

Mingrui

Mingrui

1.PLC control, windows operation, fault acousto-optic alarm and menu display.

2.Continuous surface spraying, automatic detecting initial distance and coated width.

3.Servo motor reciprocating coating, can be arbitrary set about PCB before and after the offset.Special aluminum alloy orbit and stainless steel conveyor chain.

4.Equipped with a fan-shaped spray glue valve, can be automatically.

5.Rubber valve automatically soak, to prevent clogging.

6.Inlet and outlet are equipped with communication socket, can online connection with other machines.

7.Independent paint container barrels.

8.Equipped with exhaust gas collection, outfalls.

9.Servo motor and screw module drive control mode, high rigidity, stable operation.

10.Stainless steel gun valve spraying effect is uniform, spraying quality is stable. Easy to clean, no glue leakage, no air leakage.

11.High speed and high precision, greatly improved working efficiency.

12.Easy installation; humanized computer editing program setting, easy operation.

13.The coating machine has teaching functions such as drawing points, lines, arcs, circles, and irregular curve continuous interpolation input program.

14.Continuous coating function of any point, line, surface, arc and other irregular curves.

15.Applicable glue: silicone, UV glue, polyurethane, acrylic, epoxy resin glue, sealant, hot glue, grease, silver glue, red glue, transparent paint, screw fixing agent, etc.

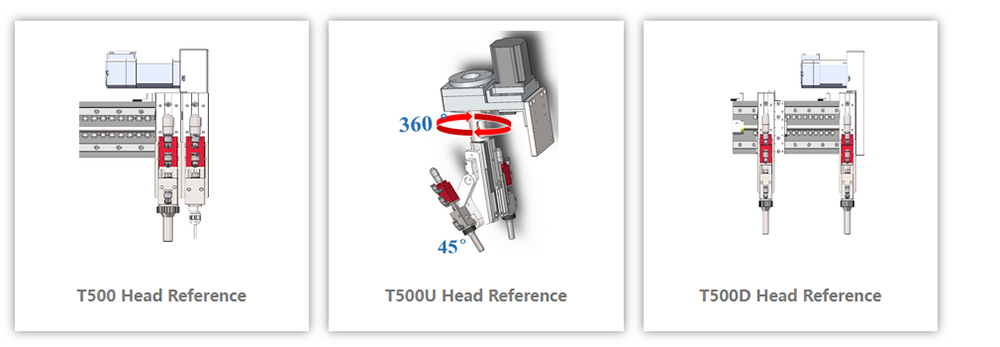

| Model | MR-T500 | MR-T500U | MR-T500D |

| Nozzle Number | 2(atomization valve 1head, precision valve 1head) | 2(atomization valve 1head, precision valve 1head) | 2(atomization valve 2head) (Option 3/4 heads) |

| Axis Number | 3-Axis X,Y,Z | 4-Axis X,Y,Z,U | 3-Axis X,Y,Z |

| Valve Rotation Angle | N/A | ±180° | N/A |

| Valve Bevel | N/A | 0~45° | N/A |

| Valve spacing | N/A | N/A | 60-200 Adjustable |

| PCB Size(mm) | 50*50 ~ 500*500mm(650*650mm Option) | ||

| PCB Thickness | 0.4~6mm | ||

| PCB Warpage | <1% | ||

| Transport Height | 920±20mm | ||

| Transport Direction | Left-Right; Right-Left | ||

| Transport Speed | Max 3500mm/s | ||

| Width Adjustment | Auto | ||

| Driver System | Servo Motor | ||

| Valve Cleaning Angle | 35 (Standard:Automatic cleaning function) | ||

| Material Volume | 1set 10L glue bucket + 1set 2L cleaning bucket | ||

| Max. Speed | 800mm/sec | ||

| Max. Component Height | Up/Down 100mm | ||

| Smallest Dispense Diameter | 0.8mm | ||

| Fan Shape Spray Width | 5~30mm | ||

| Smallest Spray Diameter | 5mm | ||

| Repeate Accuracy | ±0.02mm | ||

| Product Changeover | <5Mins | ||

| Inspect Light | UV Light | ||

| Air Pressure | 4.5~6Kg/cm2 | ||

| Power Supply | AC:220±10%,50/60HZ, 1.8Kw | AC:220±10%,50/60HZ, 2.2Kw | AC:220±10%,50/60HZ, 2.0Kw |

| Control Method | PC Control | ||

| Dimension(mm) | L1100*W1300*H1700 | ||

| Weight | Approx:700kg | ||